Mobile / Wechat / WhatsApp: 008615003170266

CangxianTiancheng Pipe Fittings Co., Ltd. Pipe Fittings Manufacturer

GLOBAL

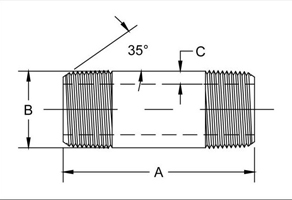

Material: ASTM A53, Sch40 standard specification for pipe steel; Welded and Seamless Black,

Threads: ANSI/ASME B 1.20.1

Pipe Size | B | A, Length | ||||||||||||||||

Pipe O.D. | Close | Space | ||||||||||||||||

1/8” | .405 | 3/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

1/4” | .540 | 7/8 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

3/8” | .675 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

1/2” | .840 | 1 1/8 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

3/4” | 1.050 | 1 3/8 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

1” | 1.315 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

11/4” | 1.660 | 1 5/8 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

11/2” | 1.900 | 1 3/4 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

2” | 2.375 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

21/2” | 2.875 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||

3” | 3.500 | 2 5/8 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||

4” | 4.500 | 2 7/8 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||||

5” | 5.563 | 3 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||||||

6” | 6.625 | 3 1/8 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||||||

8” | 8.625 | 3 1/2 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||||||

NOTE:

MINIMUM WALL THICKNESS AT ANY POINT TO BE NOT MORE THAN 12.5% UNDER NOMINAL WALL THICKNESS SPECIFIED FOR THAT SIZE PIPE.

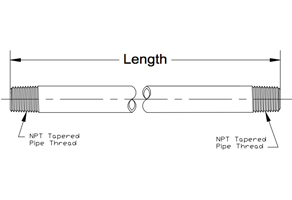

READY CUT PIPE Threaded Both Ends

Ready Cut Pipe

Material: ASTM A53 / ASTM A106 Standard Specification for pipe steel; Welded and Seamless Black,

Threads: ANSI/ASME B 1.20.1

Ready Cut Pipe

Material: ASTM A53 / ASTM A106 Standard Specification for pipe steel; Welded and Seamless Black and Hot-Dipped,

Threads: ANSI/ASME B 1.20.1

Pipe Size | Length | |||||||||

1/8'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

1/4'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

3/8'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

1/2'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

3/4'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

1'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

11/4'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

11/2'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

2'' | 18'' | 24'' | 30'' | 36'' | 42'' | 48'' | 54'' | 60'' | 66'' | 72'' |

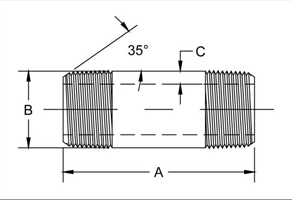

Type- Carbon steel, BS 1387; welded Black, Sandblasted

BSPT, ISO7/1.

Size | Threaded Tube BS 1387 | Length | ||||||

O.D. B, mm | Wall thickness S, mm | Running nipples | Barrel nipples | |||||

DN | inch | Light | Medium / Heavy | Light | Medium | Heavy | L, mm | L, mm |

6 | 1/8 | 10.2 | 10.2 | 1.6 | 2.0 | 16 | 30mm – 2500mm | |

8 | 1/4 | 13.6 | 13.9 | 1.8 | 2.3 | 2.9 | 18 | 30mm – 2500mm |

10 | 3/8 | 17.1 | 17.4 | 1.8 | 2.3 | 2.9 | 22 | 30mm – 2500mm |

15 | 1/2 | 21.4 | 21.7 | 2.0 | 2.6 | 3.2 | 25 | 30mm – 2500mm |

20 | 3/4 | 26.9 | 27.2 | 2.3 | 2.6 | 3.2 | 30 | 30mm – 2500mm |

25 | 1 | 33.8 | 34.2 | 2.6 | 3.2 | 4.0 | 35 | 30mm – 2500mm |

32 | 11/4 | 42.5 | 42.9 | 2.6 | 3.2 | 4.0 | 38 | 30mm – 2500mm |

40 | 11/2 | 48.4 | 48.8 | 2.9 | 3.2 | 4.0 | 38 | 30mm – 2500mm |

50 | 2 | 60.2 | 60.8 | 2.9 | 3.6 | 4.5 | 45 | 30mm – 2500mm |

65 | 21/2 | 76.0 | 76.6 | 3.2 | 3.6 | 4.5 | 55 | 30mm – 2500mm |

80 | 3 | 88.7 | 89.5 | 3.2 | 4.0 | 5.0 | 60 | 30mm – 2500mm |

100 | 4 | 113.9 | 114.9 | 3.6 | 4.5 | 5.4 | 70 | 30mm – 2500mm |

125 | 5 | 139.7 | 5.0 | 5.4 | 85 | 30mm – 2500mm | ||

150 | 6 | 165.1 | 5.0 | 5.4 | 100 | 30mm – 2500mm | ||

Carbon steel; DIN2440; welded pipe

Black, Sandblasted

DIN2999

Size | Threaded Tube DIN2440 | Length | |||

O.D. | Wall thickness | Running nipples | Barrel nipples | ||

DN | inch | B, mm | S, mm | L,mm | L, mm |

6 | 1/8 | 10.2 | 2.0 | 16 | 30mm – 2500mm |

8 | 1/4 | 13.5 | 2.35 | 18 | 30mm – 2500mm |

10 | 3/8 | 17.2 | 2.35 | 22 | 30mm – 2500mm |

15 | 1/2 | 21.3 | 2.65 | 25 | 30mm – 2500mm |

20 | 3/4 | 26.9 | 2.65 | 30 | 30mm – 2500mm |

25 | 1 | 33.7 | 3.25 | 35 | 30mm – 2500mm |

32 | 11/4 | 42.4 | 3.25 | 38 | 30mm – 2500mm |

40 | 11/2 | 48.3 | 3.25 | 38 | 30mm – 2500mm |

50 | 2 | 60.3 | 3.65 | 45 | 30mm – 2500mm |

65 | 21/2 | 76.1 | 3.65 | 55 | 30mm – 2500mm |

80 | 3 | 88.9 | 4.05 | 60 | 30mm – 2500mm |

100 | 4 | 114.3 | 4.5 | 70 | 30mm – 2500mm |

125 | 5 | 139.7 | 4.85 | 85 | 30mm – 2500mm |

150 | 6 | 165.1 | 4.85 | 100 | 30mm – 2500mm |

Noted: Other lengths and size available. Grooved end, SQ end and Bevel end available. Contact us for details.

DIN 2982 STANDARD STEEL PIPE NIPPLES

Material: For Running Nipples, Seamless or welded steel tubes according to DIN2441, For Barrel Nipples, seamless or welded steel tubes DIN2440,

Thread: Running Nipples, DIN259; Barrel Nipples, DIN 2999.

Carbon steel; DIN2440; welded, or seamless Black, Sandblasted

DIN2999, BSPT, ISO7/1

Size | Threaded Tube DIN2440 | Threaded welded nipples have a male thread on one side and a weld end on the other side. | |||||||

O.D. | Wall thickness | ||||||||

DN | inch | B, mm | S, mm | Length, mm | |||||

6 | 1/8 | 10.2 | 2.0 | 50 | 100 | 150 | 200 | 250 | 300 |

8 | 1/4 | 13.5 | 2.35 | 50 | 100 | 150 | 200 | 250 | 300 |

10 | 3/8 | 17.2 | 2.35 | 50 | 100 | 150 | 200 | 250 | 300 |

15 | 1/2 | 21.3 | 2.65 | 50 | 100 | 150 | 200 | 250 | 300 |

20 | 3/4 | 26.9 | 2.65 | 50 | 100 | 150 | 200 | 250 | 300 |

25 | 1 | 33.7 | 3.25 | 50 | 100 | 150 | 200 | 250 | 300 |

32 | 11/4 | 42.4 | 3.25 | 50 | 100 | 150 | 200 | 250 | 300 |

40 | 11/2 | 48.3 | 3.25 | 50 | 100 | 150 | 200 | 250 | 300 |

50 | 2 | 60.3 | 3.65 | 50 | 100 | 150 | 200 | 250 | 300 |

65 | 21/2 | 76.1 | 3.65 | 50 | 100 | 150 | 200 | 250 | 300 |

80 | 3 | 88.9 | 4.05 | 50 | 100 | 150 | 200 | 250 | 300 |

100 | 4 | 114.3 | 4.5 | 50 | 100 | 150 | 200 | 250 | 300 |

125 | 5 | 139.7 | 4.85 | 50 | 100 | 150 | 200 | 250 | 300 |

150 | 6 | 165.1 | 4.85 | 50 | 100 | 150 | 200 | 250 | 300 |

Noted: Other lengths and size available. Grooved end, SQ end and Bevel end available. Contact us for details.

Black pipe nipples, especially those double-ended with outer wire steel construction, are indispensable components in a variety of industrial settings. Their versatility shines through as they serve various purposes, including fluid transport, structural support, and machinery connections.

These black pipe nipples are constructed with durability in mind, using material like malleable pipe fittings, making them suitable for rigorous industrial environments. Their corrosion-resistant black finish not only provides an appealing appearance but also protects against rust and wear, ensuring a long service life.

Whether used in manufacturing, chemical processing, or construction, these double-ended outer wire steel pipe nipples can handle the demands of high-pressure systems and harsh conditions. Their threaded ends allow for easy installation and secure connections, making them a reliable choice for countless industrial applications.

Black pipe nipples, featuring double-ended outer wire steel construction, are essential components for efficient fluid control systems. Their robust design and threaded ends make them an ideal choice for applications where fluid flow, direction, and regulation are critical.

These China pipe nipple is highly adaptable, serving industries such as plumbing, HVAC, and irrigation. They allow for easy customization and assembly, enabling fluid systems to be tailored to specific requirements. Their durable black finish ensures longevity and protection against corrosion, making them suitable for both indoor and outdoor installations.

Whether you need to redirect water, control gas flow, or manage liquid transport, black pipe nipples excel in providing reliable and leak-free connections. Their versatility, durability, and ease of use make them a trusted solution for achieving efficient fluid control in various applications.

| Compare Pipe Nipples by Materials | |

| aluminum pipe nipples | |

| brass pipe nipples | |

| galvanized pipe nipples | |

| stainless steel pipe nipple | |

| Compare Pipe Nipples by Sizes | |

| king nipple pipe fitting | |

| npt pipe nipple | |

| Compare Pipe Nipples by Purposes | |

| hydraulic pipe nipple | |

| gas pipe nipple | |