Mobile / Wechat / WhatsApp: 008615003170266

CangxianTiancheng Pipe Fittings Co., Ltd. Pipe Fittings Manufacturer

GLOBAL

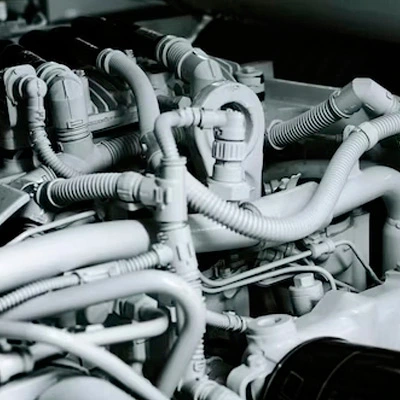

Tiancheng Custom Pipe Nipples are designed to meet your exact specifications. We work closely with you to understand your project's unique needs, ensuring a perfect fit for your pipeline system. Choose from a variety of materials, including stainless steel, carbon steel, and others, to match the demands of your specific application. Our expert team guides you in selecting the ideal material for durability and performance. With over two decades of professional experience, our team of engineering experts offers invaluable guidance, ensuring that your custom pipe nipples meet performance and safety requirements.

1. Consultation and Requirement Analysis:

The process begins with a consultation between the manufacturer and the customer. During this phase, the customer outlines their specific requirements, including material, dimensions, threading specifications, and any special considerations.

2. Material Selection:

Based on the project's needs, the manufacturer selects the appropriate material for the China pipe nipple, such as stainless steel, carbon steel, or other materials known for their durability and corrosion resistance, galvanized steel pipe nipple

3. Design and Engineering:

Engineering experts work on the design of the custom pipe nipple, ensuring that it adheres to the customer's specifications and industry standards. Precision in threading and dimensions is crucial at this stage.

4. Manufacturing and Machining:

The manufacturing process begins with the fabrication of the pipe nipple. Precision machining is employed to ensure accurate threading and dimensions. This step may involve cutting, shaping, and threading the material.

5. Quality Control:

Quality control measures are implemented throughout the manufacturing process. Inspections and tests are carried out to verify that the custom pipe nipple meets the specified quality standards and tolerances.

6. Surface Treatment:

Depending on the material and the project's requirements, the pipe nipple may undergo surface treatments such as anti-corrosion coatings or plating to enhance its durability and resistance to environmental factors.

7. Customization:

The custom pipe nipple may undergo additional customization, such as branding, labeling, or unique identifiers, as requested by the customer.

8. Final Inspection:

A final inspection is conducted to ensure that the custom pipe nipple meets all customer requirements and specifications. This includes checking dimensions, threading quality, surface finish, and overall quality.

9. Packaging and Delivery:

The finished custom pipe nipples are carefully packaged to prevent damage during transportation. They are then delivered to the customer's location as per the agreed-upon terms.

Selecting Tiancheng Steel and malleable iron pipe fittings as your custom pipe nipples manufacturer ensures access to unparalleled quality and innovation. This renowned manufacturer prioritizes precision engineering and rigorous quality control processes to produce custom pipe nipples that meet stringent standards. What distinguishes Tiancheng is its unwavering commitment to technological advancement and adaptability, ensuring that its products remain at the forefront of the industry. Moreover, Tiancheng's dedication to customer satisfaction is evident through its provision of tailored solutions and responsive service, tailored to meet the unique needs of each client. By choosing Tiancheng carbon steel pipe fittings, Malleable iron pipe fittings, stainless steel pipe fittings, customers can trust in the reliability and high performance of their custom pipe nipples, backed by a reputation for excellence and reliability in the piping industry. With Tiancheng, you gain a partner committed to delivering superior products that exceed expectations and stand the test of time.